I'm driving home and each time I change gears I can feel the clutch friction point sinking closer and closer to the floor. Argh, bugger it. Before I get home there is no clutch left at all. It makes driving kinda hard.

Yes, kinda hard - that is all. Here's a quick lesson in driving when you have no clutch. You are stopped, engine is off. Push into first gear. Start the car. Sure you will bunny hop and look like an idiot, but so long as you have a battery in fair condition it will get you moving and start the engine in first. Stop cranking once you are away. Note: try not to ever have to stop until you reach your destination!

Rev the engine up to say 3,000rpm. Start lightly pushing down out of first gear and slowly ease off on the accelerator. When the acceleration power matches the gearbox power it will pop out of first. Keep letting the revs drop and push at second gear. That is, don't crunch it into second, but lean against it. When the revs drop to the right speed for second gear, it will pop in without so much as a whimper. Really!

Continue your changes through the gears until you are in top. Now if you have to go around a corner, pop it out of top, brake to drop speed, lean against second and slowly rev the engine. When the speed matches, again, she'll pop right in. Here's a tip - practise it the next time you drive so you get the hang of it for when you need it!

Clutches in LN61 4Runners are hydraulic, not cable. What, you don't know how that works? Oh dear, I have to give you a quick lesson in that too!

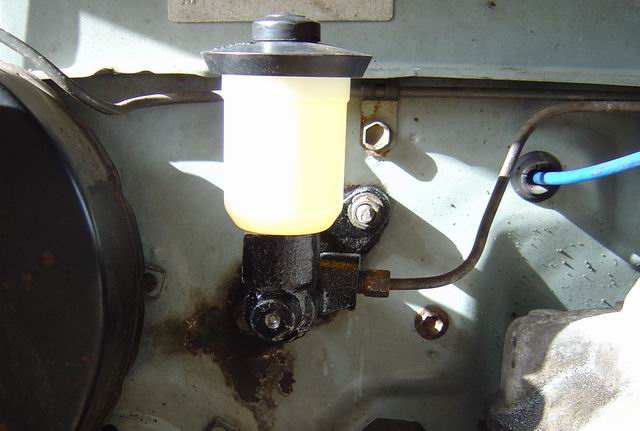

The first part of the puzzle is the master cylinder. Very similar to a brake master cylinder. There is a resovoir of hydraulic fluid on top and a little piston in a cylinder. When you apply pressure from your foot it pushes the piston in, which forces hydraulic fluid down a pressure line to a slave cylinder. The slave cylinder is also another piston in a cylinder, except this time when fluid comes in under pressure the piston pushes out, pushing the clutch.

Carrying on the story, I popped the bonnet and sure enough, no fluid left in the master cylinder. I figured it was a broken slave cylinder, got under the car and nope, no leaks there. No obvious leaks in the hydraulic lines or in the engine bay...but inside the car, there is the leak, coming out of the master cylinder.

You don't bother servicing master or slave cylinders, you just replace them. My local car shop hooked me up with a new clutch master cylinder for $AUD60 (2007). Disconnect the split pin holding the clutch pedal to the master cylinder in the cabin. Undo the hydraulic line into the master cylinder, undo the 2 bolts holding it on. Take off the connector on the old cylinder, throw it over your shoulder.

Attach the connector to the new cylinder, pop it in place, bolt it up connect the lines. Note that the hydraulic line threaded connector is tapered so you don't need thread tape - just wind it in tight and it will pressure seal just fine. Fill up the master cylinder with fluid. There will be air bubbles in the system, you need to bleed them out.

Underneath, on the slave cylinder there is an air bleed nipple. I keep a bit of clear plastic pipe in the shed just for the purpose of bleeding hydraulics. Loosen the nipple, push on your clear plastic pipe. Olde school bleeding had one operator pushing on the pedal while the other tightened and loosened the nipple. Apparently this isn't the way to do it anymore. Brake shops use a power bleeder which sucks the fluid through, nice if you have one.

These days I back off the nipple and let gravity do its work. Keep topping up the fluid resovoir - don't let any new bubbles in. If I'm in a hurry a bit of pedal pressing will help things along. Keep going until the fluid coming out you plastic pipe is clean, ie you have flushed the system. You shouldn't see any air bubbles coming out the pipe either. Tighten up the nipple and you are done.

You should get clutch pedal action back straight away. Adjust the connector so the clutch friction point is in the place you like it; I tend to keep it close to the floor because I can be abusive on clutches, and have bent several clutch forks in my time. Keeping it close to the floor means a bit less stress...quicker changes too ;)

database

database