Okay so you've been hearing some noises under the car for a while, now it is getting a bit loud; you've tightened up the exhaust flange bolts, you've been under the car while it is stationary and running and tightened all the lose body panel bolts - but there is still drive train noise.

...Noise particularly during acceleration and deceleration, it was kind of whiney at first eventually turning clunk clunk clunky and downright disturbing. Waiting for something to go BANG!? ;)

Well check your propeller shaft universal joints! It's easy, get under the car and hold the propshaft one side of a universal joint, hold the other side, and see if you can get any movement. If you can't, great. Grab your grease gun and squirt some grease into it anyway, until it starts to come out all four spider joint bearing races. If you're getting a clunk clunk clunk on the uni-joint, you'll need to read on.

On a 2WD there is (usually) only one uni-joint at the differential end of the propeller shaft, on a 4x4 there is (most likely) four - two per prop shaft. For me, the rear propshaft rear uni-joint was stuffed. Put some marks on the propshaft either side of the uni-joint with your paint pen so when you pull it apart you'll know which way it goes back together. Take the propshaft off. If you don't know how to do that, stop reading now, this job is too hard for you.

Note that on a 4x4 propshafts are flanged on both ends - whereas 2WD it probably is moving spline into the cog swapper. The propshaft has two parts, which is essentially a spline anyway, also give that a bit of grease.

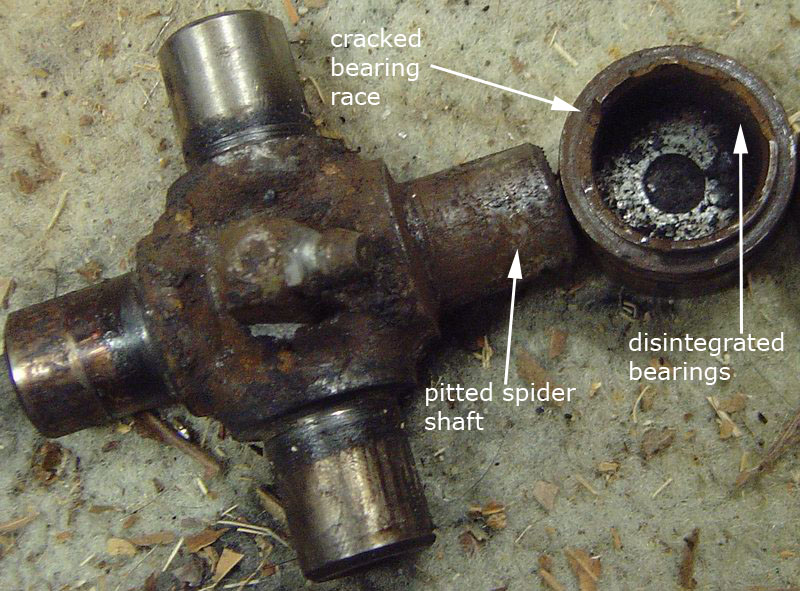

The universal joint has the middle "spider" and 4 bearings pressed in - two on one "end" of the joint and two on the other "end". They have been cunningly designed however so you can pop the bearings out either end across a spider to disconnect that "end". Ah, you'll need to look at the pictures, it will explain it better.

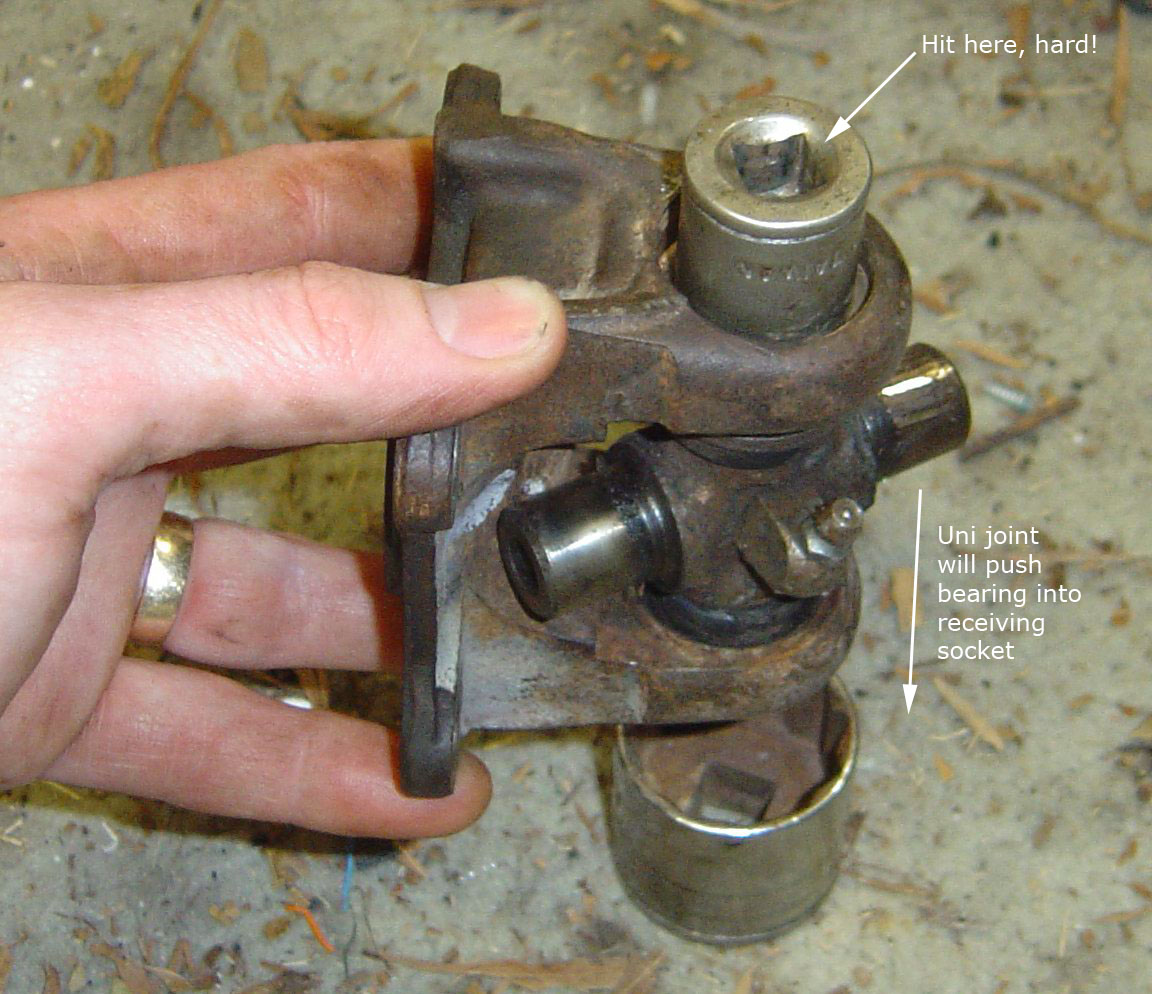

There will probably be circlips under a lot of dirt and grease - clean it up and remove them. Now if you have a really big vise you are in luck, you can use the vise to press the bearings out. My vise just didn't quite open wide enough. Basically, what you want to do is push one bearing in which pushes the opposite side bearing out, then turn it around and push on the other side to pop the first one back out. Then repeat for the other half of the joint.

Easy way is to use a socket as a drift, and a big socket, bigger than the bearing, as a receiving container. If you do this in a vise it's gentle, I did it by bashing the crap out of the first socket with my hammer. It was a sacrificial socket ;)

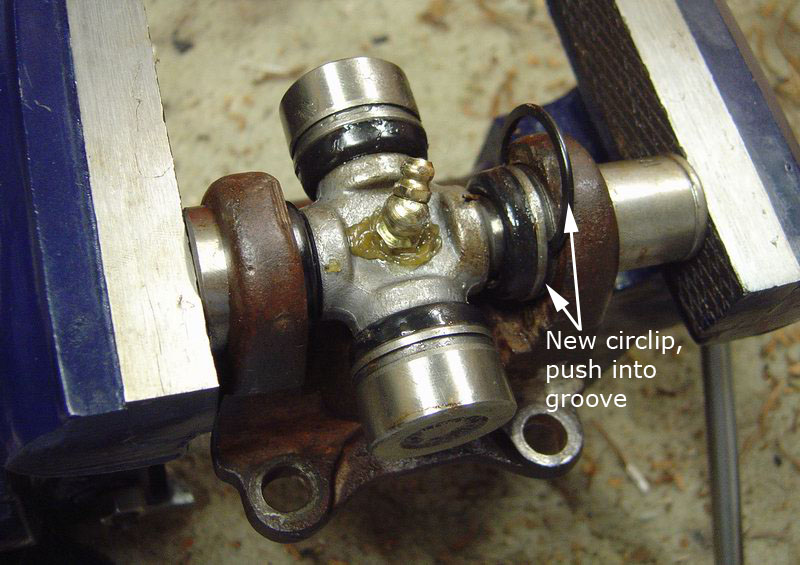

Once all four are out, grab your new one uni-joint, AUD$28(2008) and press the first half in. When it is just in the circlip groove will line up, so pop a clip in. Both sides. Repeat for the other half. Now think about which direction the grease nipple should point - on the forward side or the backside, so you can squirt grease into it!

Also don't forget to put it back together lined up with your original markings. Propshafts are dynamically balanced; even if yours is full of dents and dings from running over rocks, it is still far more likely that it will prefer to be put back together the same way it came out.

Put the propshaft back on. Go for a drive. Be amazed at how quiet the drivetrain now is...and another skill is added to your collection ;)

database

database