The XR has always been very hard to start. At first people would say "heh, yeah, those single pot 600's are buggers to start." When JAW was starting to walk around in circles because his right leg was twice as big as his left leg, he began suspecting carby troubles. "It only starts when it has the exactly the right amount of fuel in the pot it seems. Too rich, it wont start. To lean, it won't start."

Finally a wise man said "JAW check your spark." "Yeah, of course there is a spark, it wouldn't run at all if it didn't spark!" "Humour me."

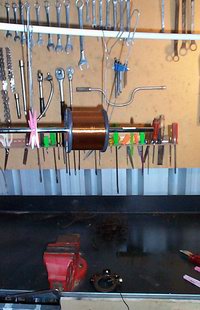

Stator in the rotor cover.

Weak spark?

Behold and lo, the was the wimpiest pale spark you've ever seen; it would have battled to fight it's way out of a wet paper bag. That kinda makes sense - a fat spark would ignite fuel in up to the worst conditions, but a wimpy spark would need "perfect" conditions to get the show on the road. Well that's what I thought anyhow.

So what does a weak spark mean? Looking at a motorcycle sparking system there is the spark plug, the ignition coil, high tension lead, wiring, the pulse sensor, the CDI and the stator exciter winding to generate the power.

The problem was isolated using another bike to swap and test parts - it had to be either the CDI or the exciter winding. But do you think you can get a motorbike shop to test a CDI? "Hey guys, have you got an XR600RJ that you can verify the operation of this CDI on?" "Oh, no no no, you must go and pay $'00 to the Master Motorbike Electricals Guru, it's all magic, only he knows how it works." Yeah, "blah blah blah" is all I heard.

Gotta be the exciter winding...

JAW makes a bold decision: "CDIs are electronics. They either work, or they don't work. I reckon that tiny, thin winding of enamel wire on the stator that is subject to heat, oil and works from a permanent magnet is *far* more likely to be the problem.

Before you go any further, I want to know how it all works.

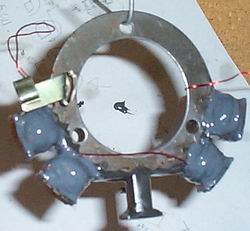

Exciter winding at the top.

Four Lighting windings either side.

Okay! Firstly, there are two separate circuits on the average bike - a low voltage power source for running accesories such as headlights and indicators, and a high voltage power source (known as the exciter winding) for getting the CDI to spark. Bikes without lights will only have an exciter winding - who needs a headlight anyway? ;)

Now the rotor, the thing that spins around the stator, is magnetic. It has several poles, you know, Norths and Souths, on it. On this particular bike there are 6 Norths and 6 Souths. As the rotor spins around the exciter winding, thanks to some rather convenient physics current will flow in the winding. As a North pole passes, current goes up, North then swings back to neutral (ie no magnetism) current goes to zero, South pole passed, current goes the other way. Yep, it's AC (Alternating Current).

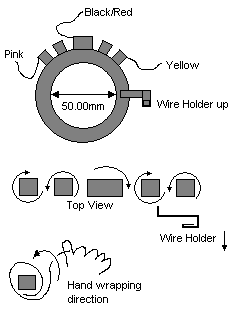

Winding notes...

The more windings you have the higher the voltage. By winding the exciter with *heaps* of turn with really thin wire you get high voltage, low current. Using thicker wire, less turns, lower voltage, higher current.

They got clever on the lighting side of things. The four windings are just one piece of wire, but it is wound clockwise on the first pole, anticlockwise on the second pole, and so on. Why? They are positioned so exactly as a North pole is going past the first winding a South pole is going past the next winding. What does that give you? Well, the current flows depending on which way the winding was turned. So, in effect, by having the opposite pole and the opposite winding direction, the currents all add up. If you didn't alternate the winding directions, the currents would actually cancel out...

The advantage is of course that you get quadruple the output - each individual winding is good for say 3V but 4 of them gives your 12V. Note that the actual voltage is dependent on rpm but then controlled by a regulator to maintain 12V and then rectified where necessary, but that's another story.

The empty pole, ready to receive some wire.

Hmm, the right most lighting pole is looking

a little black...

Rewinding, a process.

On with the story. Specifications for an XR600 between 1985 and 1990 state that the exciter to ground resistance should be between 230 and 320 Ohms. My old one came in at 370.

Ripping off the old winding revealed the problem. Enamel had been baked black - but there were no short circuits. That's what you'd expect if the enamel had been baked all the way through, that the widings would be shorting out to other parts of the winding. It seemed the wire had just corroded and was so thin in places it broke apart as it came off. What must happen is as the copper itself is getting old and sad, its resistance increases and its ability to carry a current diminished. Hard to start but will run okay.

Set yourself up first, you want to

be able to drag wire off the spool easily.

You'll need to find yourself a big spool of hair-thin enamel winding wire. I came across this one from the olde man in laws shed. It's 0.132mm, vintage 1978...it's slightly fatter than the existing windings, so to replace the same number of turns it will be a physically bigger winding. Oh well.

Try and get good quality winding wire with the highest temperature rating on it as possible. Inside the engine can get really hot being aircooled - much hotter than a water cooled engine.

Set yourself up so the wire can freely pull off the spool and just wrap, wrap, wrap. It's suprisingly strong for hair-thin wire but don't take any chances. Do a few stress tests on it before you begin, see how easy/hard it is to snap it. You want one winding, you don't really want any joins.

If you do break it...well, if you weren't too far along, start again, if you were near the end carefully strip away some of the enamel and solder to re-attach.

After about an hour, yeah, just an hour, it was wound to where I thought it should do. It was a fair bit bigger than the old coil.

Halfway - careful does it!

So how do you know when to stop? I decided to carefully peel off a bit of enamel and do a resistance check. I found couple of scrapes with a sharp knife removes enough enamel for a connection. The first check was 162 Ohms. So I kept going, estimated how much bigger it should be to get the desired resistance. Second check, 250 Ohms. That will do.

(I had made a check with some plasticine that 14mm was the maximum height before it would scrape. Put plasticine or similar on the stator, put the whole thing back together, rotate the engine, pull apart, find out how big the winding can be if required.)

Carefully solder on some flyleads and expoxy the thing in place to protect those precious little windings. I used some devcon I had lying around, it isn't conductive, it is tough as, withstands oil and temperature.

It seemed to do the job.

Results

Okay, the winding was a success. The bike started nice and easy which was a pleasant suprise; but as time went by it got less easy. Until finally, a year later, out in the bush, it refused to start.

What could have happened?

Measuring the resistance back in the shed showed the resistance was still 250Ohms. Kickedy kick, nothing. Retest the resistance down to 150Ohms. Huh? a while later its at 210Ohms.

Right, its coming out again to find out what went wrong and fix it.

First thing I did was check the how big a winding you could put in there physically. The plasticine test revealled 14mm deck height maximum.

While degreasing the winding I found out the first problem - water dropped the resistance right down. Ah ha! Must be an internal short. As I unravelled it the truth became clear. Oil and heat had broken down the enamel protective coating and caused intermittent shorts. But how did the oil get in?

Sure, I epoxied the windings on the outside - but oil found it way past the exciter plastic spool from the _inside_. The new attempt was firstly going to have to be plastic spool-less and secondly epoxied all the way! The Devcon epoxy used proved up to the heat and oil challenge - even though it had changed colour from gray to dark brown.

Stripped back and re-epoxied.

With a bare stator in my hand, first thing to do is "dunk" the thing in epoxy - so that the first windings aren't sitting on metal but sitting on a protective coating of epoxy over the metal. This is similar to how they come from the factory.

I rang around a bit and found that there was no such a thing as high-temperature enamel. Normal enamel winding wire is rated to around 120-130degC. Super-enamel can go out to maybe 200 but I couldn't source any locally.

I decided to stick with the wire I used last time, but from the moment the first windings went on I was popsticking on epoxy for a "total seal". Nothing was going to get in there. This time I wound all the way out to 310Ohms. The winding was looking pretty oblong since there was no spool to neatly wind onto, but it hasn't caused a problem so far.

Lighting circuit done.

The lighting circuit copped some 0.8mm winding wire worth about $5 from the local electronics store. I counted 64, 66, 70, 65 turns pulling the old wire off - I decided to wind on 75 each "since the rotor was old and the magnetism was probably not as good as it was in 1987".

While I was there I also replaced the insulated wire out of the rotor case up to the CDI®ulator. Note that normal wire is no good - find yourself some silicone insulated wire. Not only will it take up to 200degC but it is also immune to the effects of oil and other nasties.

So where are we at?

The lighting circuit 75 turns was a bad call. It blew the regulator - the voltage and/or power went too high. I put a test 24V 100W globe on the unregulated winding, the voltage went up to 30V and the globe blew; not even close to full revs. That will require some thought - current plan is a home made regulator and perhaps to run the system at 24V instead of 12. That would have the advantage of using all the available power those extra windings added on - 100W or more instead of the measly 50 or so the bike came with. It may yet be a good thing.

The exciter winding has worked yet again, big spark, did not kill the CDI. It is pumping out around 90VAC at idle. Now it's the waiting game - will the enamel take the heat fully epoxied or will the same thing happen?

It ran fine for more than a year, but again the winding broke down, not as quick this time, but it still got hard to start again. Eventually I gave this bike away, and the new owner bought a shop made stator for it.

The conclusion is there is no magic, no trickery, but the environment inside an air cooled engine is harsh so you need good enamel wire and good epoxy! Good Luck and Good Skill.

JAW

database

database