There are a lot of reasons why your BF Falcon won't start, this is one of them.

After a year since replacing the starter motor I was disappointed that again the car wouldn't start. But unlike the previous symptoms, there were no clicks, no attempts to start, the battery seemed fine. I'll keep this story short - it was the automatic transmission interlock preventing the start.

A quick note for anyone who wants to know when their car isn't starting whether it is an interlock or the starter motor: Under the bonnet there is a fusebox with a starter relay. (You can find a copy of the BA/BF Falcon wiring diagram on the internet.) Pull out the relay, and jump the output socket side of the relay directly to 12V. This bypasses the ignition key switch, the autotrans switch and the ECU. Either the solenoid on the starter will pull in and the engine will crank or the starter solenoid is buggered. WARNING! when you do this, have somebody in the car with the foot on the brake - if the gearbox is not in park or neutral the engine will turn over and the car could take off.

Automatic transmission cars shouldn't be started when in gear for a number of reasons. So the manufacturer has included a switch to detect it. If the switch has failed, then the starting circuit won't work. This wasn't the switch, in fact the BF Falcon switch is pretty fancy, the dash actually shows what gear you have selected - P, R, N, D. Sometimes if your switch is failing then ramming it through the gears might temporarily get you going again. The giveaway on this was that the gear selector mechanically felt very loose and the dash said "D" no matter what position the selector was in.

Looking underneath was the answer - the end of the cable from the selector inside to the arm on the side of the gearbox had snapped off. A quick bit of googling revealed this is a common problem for these cars, and the new cable is around $150 and you have to dismantle a lot of the interior to fit it. More googling revealed this guy who had done his own hack and I thought it seemed like a good idea. So I rummaged through my box of bolts and bits and came up with a very similar solution.

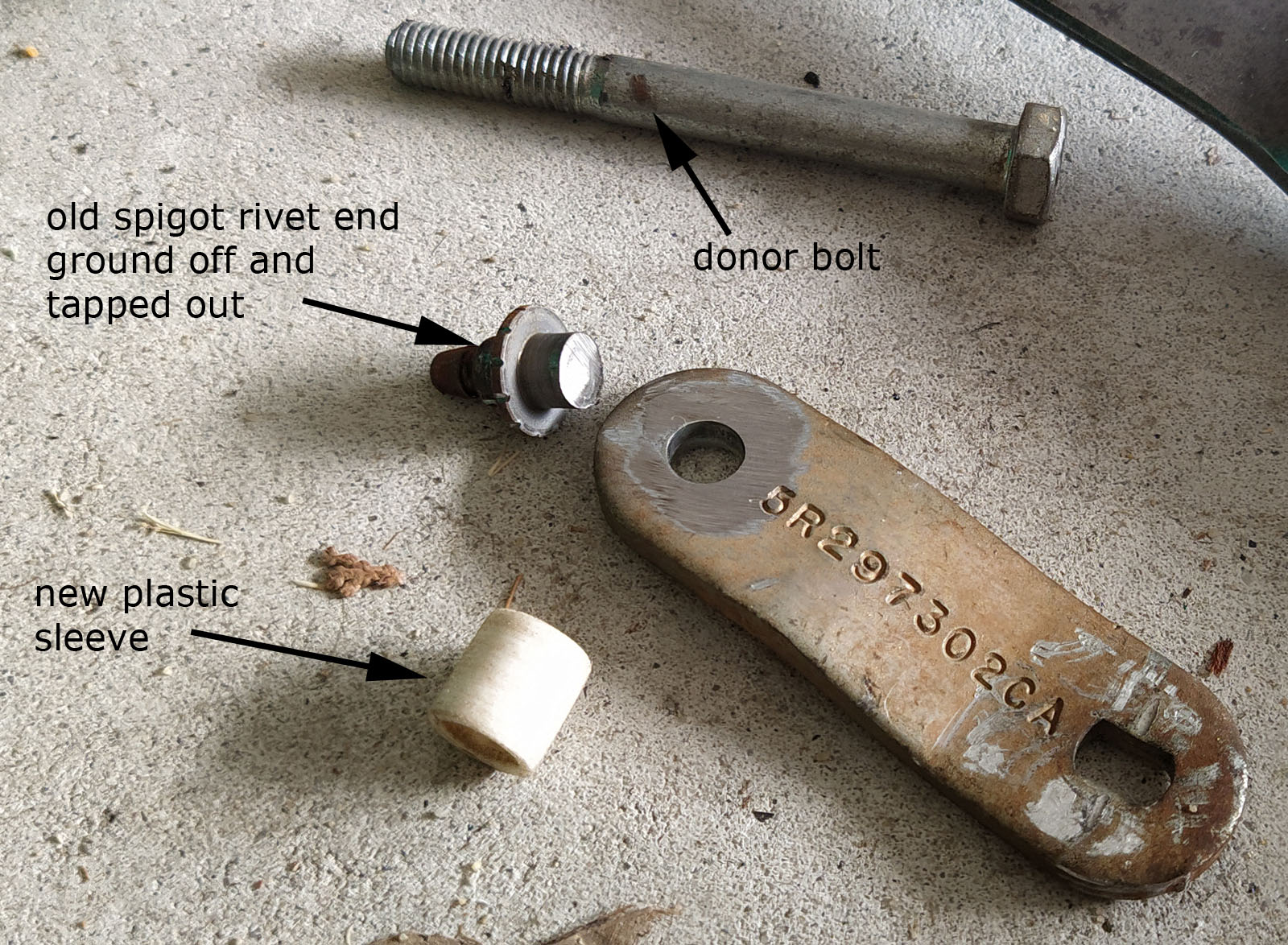

Remove the selector arm from the gearbox. Grind off the back of the riveted on spigot, then tap it out. I found a bolt that was the same size as the spigot hole, which conveniently was the same thread as the bolt for the selector arm. That just seemed right, but it's not important. What took me the longest was making a new sleeve to replace the old one. I don't have a lathe, so I started with a piece of plastic that had a hole in it the same size as the bolt, and with it spinning in my drill I "turned down" the outside diameter until it fit in the end of the selector cable. Keep turning down, test fit, turn down, test fit, until you are there.

At this stage I pushed the bolt through the hole so the amount of unthreaded shaft was the same length as my new sleeve/bush, and welded the bolt in place. I then ground the back half of the bolt off, cut off some thread length too, and gave it a quick bit of paint so it wouldn't immediately rust.

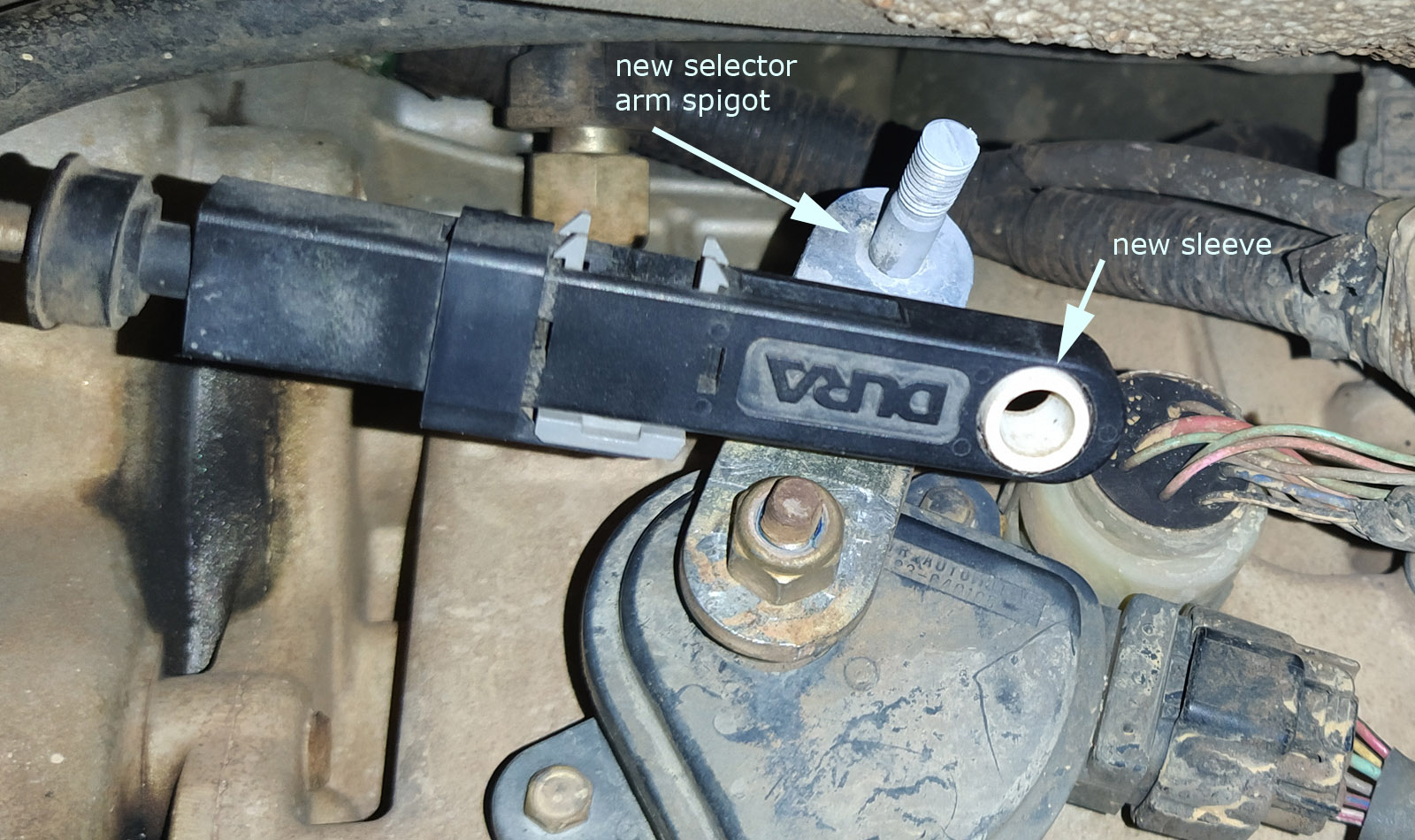

After that it was straight forward. I used a nylon locking nut and washer and didn't screw it al the way on. The idea is that the new sleeve will rotate on the bolt - the sleeve is pressed into the end of the cable. This is similar to how it used to be - I didn't want to use the end of the cable as a wear surface, although it is pretty touch plastic. Plenty of grease and it all worked fine.

We will see how long this fix lasts!

database

database