Here's another story highlighting my inability to look for the simple things. I'm not sure if it just an engineers mindset, or it is an infliction that affects a wider portion of the population - but when you assume you make an ass of u and me...

Lets start at the beginning.

I'd been away for 3 weeks and nobody had run the hilux while I was gone; when I got back I took the old girl for a run - started nicely, got me about 300m down the road, conked out. Wouldn't restart.

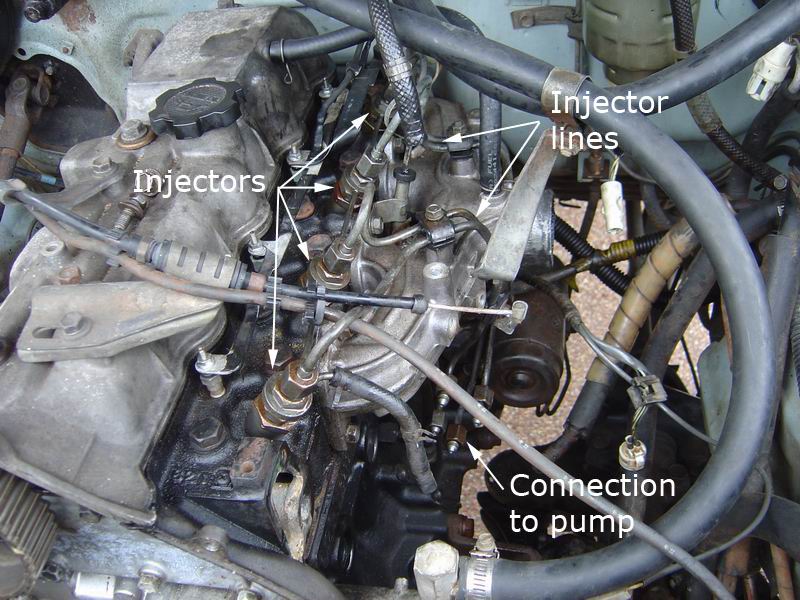

First diagnosis was at the fuel filter - disconnect the outlet and a couple of squirts showed there was fuel available. Okay; disconnect an injector line, crank the engine...uh oh, nothing - the injector pump must be stuffed!

Okay, here's a quick lesson:

Olde school diesel injector pumps - and a lot of new school ones - are mechanical. They are rotated at the same speed as the camshaft; in the case of the Toyota 2L motor they are in fact on the same timing belt as the cam. Inside them is lots of springs and diaphrams and other trickery which has one purpose: at the right time a certain amount of diesel is pushed out one of the 4 holes in the back.

4 holes because this is a 4 cylinder engine; ie one hole per cylinder. The size of the diesel shot is determined by how far your foot is planted to the floor. The injector pump creates immense pressure, which is kinda handy because the fuel injector requires an immense pressure to operate.

When the shot of diesel comes out one of the 4 holes, it pushes up through an individual injector line to the fuel injector. The main spring inside the fuel injector is pushed aside by the pressure allowing diesel to be squirted hard into the engine. The pressure drops off as the shot is delivered and the fuel injector snaps shut again, awaiting the next shot. Pretty simple huh.

I was so sure the injector pump was broken that I lined up a second hand one; I spent the better part of a day pulling the first one off and putting the second one on. Check out the article on timing belts as to how to get the injector pump timed right. Yes; the timing needs to be right. You don't want that shot of diesel to be delivered at the wrong time do you?

But anyway, with the replacement injector pump on - I had exactly the same problem; no fuel going to the injectors. Oh no, it mustn't be the injector pump!

Another thing to know about injector pumps is; well, once the engine is running how are you going to stop it? While the engine is running diesel is being pumped in; while diesel is being pumped in the engine keeps running... The only way to stop is to actually prevent fuel from getting into the engine. This is done using an electrical solenoid fuel shutoff valve right at the start of the pump. Put power onto the solenoid, fuel is allowed in, take power away, no fuel - no run.

Now I'm not altogether stupid; I'd checked the fusebox and yes; the "engine run" fuse was okay; the solenoid was getting power when the key was in the run position. At this stage however I pretty much knew it was an electrical issue and was just starting preparations to kick myself for not checking the simple things first. I disconnected the solenoid and ran a test cable straight to the battery. CLICK. CLICK. Solenoid seems fine. If I now try the same with the loom wiring. click. cli... Hmm, that doesn't feel like a strong solenoid action. Multimeter...hmm, about 9V. There is some voltage drop on this cable...peel back the insulation and whaddaya know, the wire to the run/stop solenoid is corroded and not able to properly hold the solenoid in.

I replaced the stuffed section of wire and bang, away she went.

So although it is good to keep my diesel engine skills fresh, it was a bad diagnoisis that cost me time and money. I put my original pump back on, put the engine back together and took her for a lap around the block. Just as slow, rattly and noisy as ever :)

database

database